Quadrant 3

Complicated Gaussian world (interdependent relationships of normal distributions)

Definition

Q3 focuses on complex systems where many independent parts – their stand-alone functionality often thoroughly stress tested – come together and form a complex system. Most feats of engineering fall into this category. Risks are occasionally mechanical but, as time and iterative learning lead to improvements, errors are predominantly human.

Criteria

- Errors are rare, yet even minor ones can lead to extreme consequences for the system as a whole.

- The distributions of the system components are Normal, yet the sheer number of components renders the system Complex.

Examples

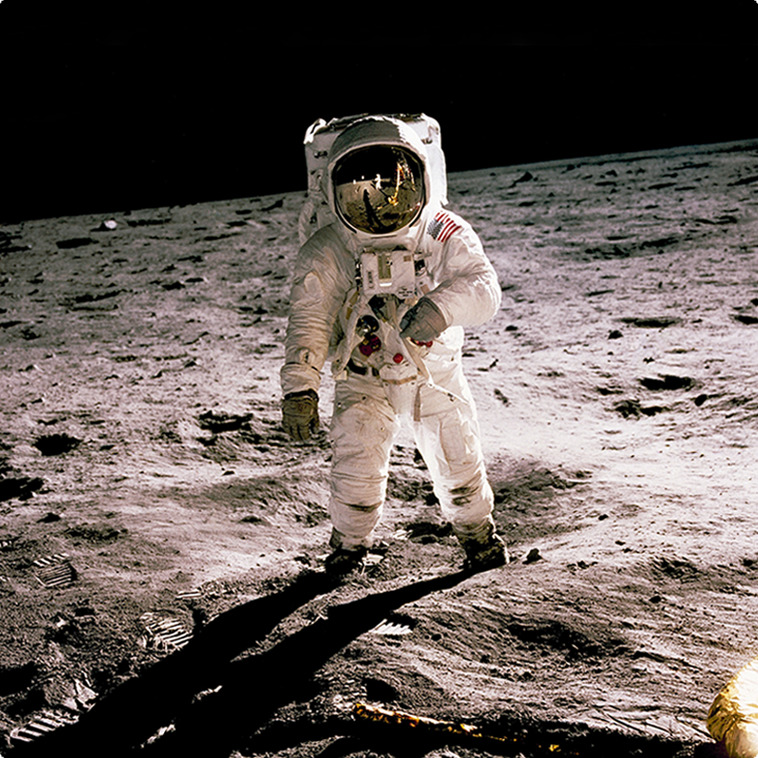

- The first human landing on the moon – clearly a complex undertaking – involved the interaction of gravity, orbits, earth spin, pressure, oxygen, electrical, mechanical, propulsion engineering and numerous other parts and systems. Computing power was laughable by today’s standards. Yet the landing was precise and without incident. The lunar landing was a truly complex task where the expected result fell within a very small range of possibilities. Yet, any minor outlier could have resulted in drastic consequences for the astronauts and – as we saw 16 years later after the Challenger space shuttle disaster – to the US space programme.

- The US/Ontario power blackout of August 2003, caused by a software bug in an alarm system, shut down 508 generating stations and 265 power plants, overloaded telephone and mobile circuits, caused water pressures losses and contaminated supply, shut down airports and train systems, affected 55 million people and caused an estimated 100 deaths.

Risk Management Tools

- Q3 risks can only be managed by introducing sufficient redundancies and buffers into complex systems. Initially, such management tools are often avoided since they can incur costs and hurt short-term profitability. Yet, almost without exception, they improve long term profitability by reducing disasters and downtime.

- As Walter Ammann noted in his presentation to the 2009 Global Risk Forum in Davos: “Resilient systems reduce the probability of failure, the consequences of failure and the time needed for recovery. Resilience is both inherent strength and the ability to be flexible and adaptive after environmental shocks and disruptive events.”

- Learn the building blocks of a resilient system, referred to in various research papers as the 3, 4 or 5 R’s. 1) Redundancy, 2) Reliability, 3) Robustness, 4) Resourcefulness, 5) Rapid Response and 6) Regulation.

- Hire smart and skilled operators.